RESEARCH

- HOME

- Research

- Overview - Korean

OVERVIEW - ENGLISH

● Welcome to Lee Group – Green & Sustainable Separation Laboratory!

Up to now, 10-15% of the global energy has been consumed in chemical separation processes. Although the world is in the middle of transforming the heavy dependence on fossil fuels to renewable energy sources for sustainable development, we expect that the fossil fuels may still dominate the global energy for the time being in the light of too many existing technical challenges for renewable energy. With that in mind, we believe that membrane-based separation techniques may be a promising tool to significantly reduce the energy consumption associated with the conventional separation processes. Also, it is vital to understand the fundamentals of transport in those media as well as to design advanced materials in order to reduce the energy cost for the current separation processes. Our research group mainly focuses on understanding the fundamental transport of gases or liquids in various materials including polymers, polysilsesquioxanes, metal-organic frameworks, carbon molecular sieves, and their combined materials by utilizing various characterization techniques. Some current research activities are described in more detail as below. (Updated on Jan 18, 2021)

● Field of study

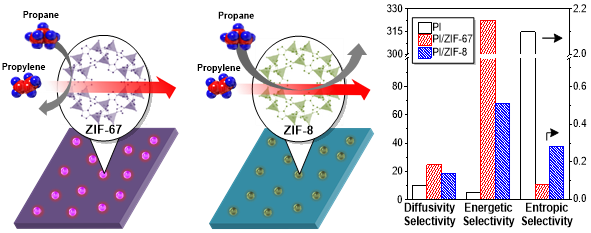

1)Mixed matrix membranes for olefin/paraffin separations

Olefin/paraffin separation is one of the most important processes in the petrochemical industry due to the highly utile applications of those gases in our everyday life. Propylene is the second most important feedstock next to ethylene with its annually increasing demands: the 90 million tons of global demand in 2014 was expected to continually increase, exceeding 130 million tons in 2023 based on IHS Chemical North American Propylene Supply Study. Currently, propylene/propane (i.e., C3H6/C3H8) separation is implemented mainly by highly energy-intensive cryogenic distillation due to the similar physical properties between C3H6 and C3H8 (i.e., Tb of C3H6 and C3H8 is -47.6 ℃ and -42.1 ℃, respectively). Membrane-based separation technique is promising due to its good energy efficiency as well as low capital cost. Conventional polymeric membranes, however, have been yet to reach and/or surpass the performance limit so-called “the upper bound”, albeit their great advantage of high processability. Mixed matrix membranes (MMMs) are essentially hybrid membranes consisting of inorganic molecular sieves (dispersed phase) and polymeric matrix (continuous phase). Our recent work is focused on engineering the structure of zeolitic imidazolate frameworks-8 (ZIF-8) and polymer matrix for enhanced C3H6/C3H8 separation performance.

1. Heseong Anǂ, Sunghwan Parkǂ, Hyuk Taek Kwon, Hae-Kwon Jeong, Jong Suk Lee*, A new superior competitor for exceptional propylene/propane separations: ZIF-67 containing mixed matrix membranes, Journal of Membrane Science 526, (2017) 367-376

2. Jin Woo Ohǂ, Kie Yong Choǂ, Ming-Yang Kanǂ, Hyun Jung Yu, Dun-Yen Kang*, Jong Suk Lee*, High-flux mixed matrix membranes containing bimetallic zeolitic imidazole framework-8 for C3H6/C3H8 separation, Journal of Membrane Science 596 (2020) 117735

3. Heseong Anǂ, Kie Yong Choǂ, Seoin Back, Xuan Huy Do, Jae-Deok Jeon, Hyung Keun Lee, Kyung-Youl Baek*, Jong Suk Lee*, The significance of the interfacial interaction in mixed matrix membranes for enhanced propylene/propane separation performance and plasticization resistance, Separation and Purification Technology 261 (2021) 118279

2) Carbon molecular sieve membranes for natural gas processing

Natural gas processing is one of the largest industrial applications of gas separation membranes. Carbon dioxide (CO2), a common impurity in natural gas, should be removed to a level of < 2% based on the U.S. gas pipeline specification in order to minimize corrosion of the pipeline as well as to obtain high heating value. Also, some low-quality natural gas reserves must undergo a nitrogen rejection process to satisfy pipeline specifications which require that the total concentration of inert gases be less than 4%. Membrane technology is promising due to its good energy efficiency and small footprint; however, it requires highly delicate molecular level engineering to improve separation efficiency as well as high pressure CO2-induced plasticization resistance. Carbon molecular sieve (CMS) membranes are a promising candidate for natural gas processing due to their peculiar pore structure-induced excellent separation performance. Recently, our group reported a simple and effective method of fabricating high-performance CMS hollow fiber membranes with excellent CO2/CH4 separation performance by pyrolysis of rigid double-stranded siloxane containing precursors [1]. Also, we developed CMS membranes with excellent N2/CH4 separation performance and identified the effect of SiOx phase on enhanced N2/CH4 separation performance.

1. Ju Ho Shinǂ, Hyun Jung Yuǂ, Heseong An, Albert S. Lee, Seung Sang Hwang, Seung Yong Lee, Jong Suk Lee*, Rigid Double-stranded Siloxane-induced High- flux Carbon Molecular Sieve Hollow Fiber Membranes for CO2/CH4 Separation, Journal of Membrane Science, 570-571 (2019) 504-512

2. Hyun Jung Yu, Ju Ho Shin, Albert S. Lee, Seung Sang Hwang, Jeong-Hoon Kim, Seoin Back*, Jong Suk Lee*, Tailoring selective pores of carbon molecular sieve membranes towards enhanced N2/CH4 separation efficiency, Journal of Membrane Science 2021 (In Press) (Editor’s Choice)

3) Biomimetic patterning of polymeric membranes for enhanced anti-biofouling performance

Surface contamination by biological matter, so-called biofouling, is a persistent problem for materials that are exposed to aquatic environments because it degrades the materials’ function and performance efficiency. Specifically, most polymeric membranes for water treatment suffer from serious performance deterioration by biofouling, which reduces the operating efficiency of the membrane process. Recently, we demonstrated that the Sharkskin-mimetic patterns can significantly suppress the biofouling of desalination membranes and identified the anti-biofouling mechanism of topologically surface modified membranes. We are engineering the surface topology and chemical structure of polymeric membranes for enhanced long-term separation performance.

1. Wansuk Choiǂ, Changhoon Leeǂ, Dahye Leeǂ, Young June Won, Gi Wook Lee, Min Gyu Shin, Byoungjin Chun, Taek-Seung Kim, Hee-Deung Park, Hyun Wook Jung*, Jong Suk Lee*, Jung-Hyun Lee*, Sharkskin-mimetic desalination membranes with ultralow biofouling, Journal of Materials Chemistry A 6 (2018) 23034-23045

2. Wansuk Choiǂ, Changhoon Leeǂ, Cheol Hun Yooǂ, Min Gyu Shin, Gi Wook Lee, Taek-Seung Kim, Hyun Wook Jung*, Jong Suk Lee*, Jung-Hyun Lee*, Structural tailoring of sharkskin-mimetic patterned reverse osmosis membranes for optimizing biofouling resistance, Journal of Membrane Science 595 (2020) 117602

3. Cheol Hun Yooǂ, Gi Wook Leeǂ, Wansuk Choiǂ, Min Gyu Shin, Changhoon Lee, Jeong Han Shin, Yong Son, Byoungjin Chun, Jung-Hyun Lee, Hyun Wook Jung, , Jong Suk Lee*, Identifying the colloidal fouling behavior on the sharkskin-mimetic surface: In-situ monitoring and lattice Boltzmann simulation, Chemical Engineering Journal 405 (2021) 126617